How can we help?

Our Experts Are Ready to Create Precision Shaped Stainless Steel Wire For Your Project!

Stainless steel is a common choice in harsh, corrosive environments. Stainless Steel is an alloy of iron that contains at least 10.5% chromium, which reacts with oxygen to form a thin, protective, and self repairing layer that prevents rust and corrosion.

In addition to chromium, other alloys such as molybdenum, nickel and nitrogen may be added to create different grades- each with properties that make it suitable for a variety of applications. The best type of stainless steel for a particular application will depend on the specific requirements of that application. Factors such as corrosion resistance, strength, weldability, and cost should be considered when making a material choice.

Stainless steel wire has a wide range of applications, including:

Medical and Surgical:

Used for medical instruments, sutures, and orthodontic applications

Construction:

Used in architectural applications like railing and fencing

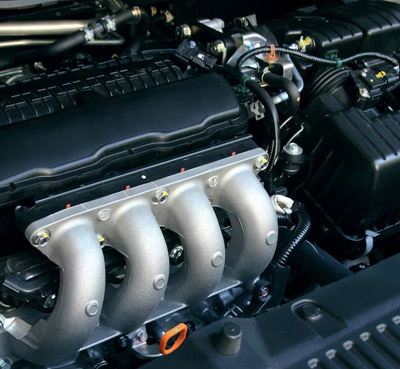

Automotive:

Used for various automotive parts and components

Manufacturing:

Used in the production of springs, fasteners, and wire mesh

Electronics:

Used for connectors, antennas, and sensors

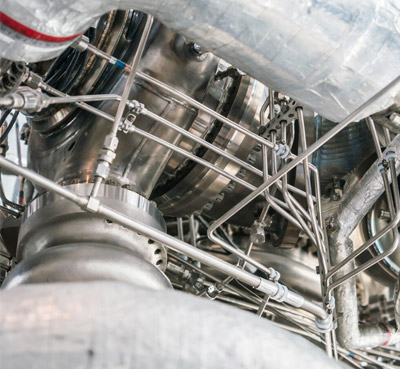

Aerospace:

Used in aircraft components such as flexible hoses/shafts, hoses and valves

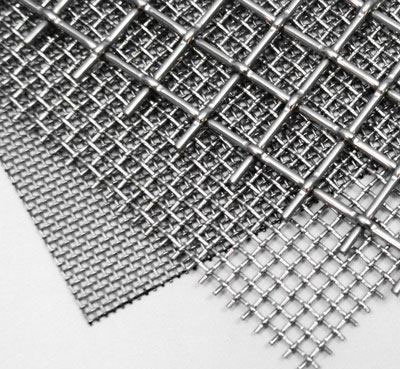

Mesh/Screens

oil, gas, water filters, paper pulp meshes

Art and Design:

Utilized in sculptures, jewelry, and artistic projects

Stainless Steel Grades

There are five main types or families of stainless steel, each with its own unique properties and advantages. Grades of stainless steel are sorted between these five families:

AUSTENITIC

The most common type of stainless steel, known for its excellent corrosion resistance, formability, and weldability.

201 | 204CU | 301 | 302 | 302HQ | 303 | 303SE | 304 | 304L | 304V | 304LV | 305

310 | 310S | 316 | 316L | 316 LVM | 317L | 321 | 330 | 347 | AL-6XN® | INCOLOY® 25-6MO

FERRITIC

Less common than austenitic stainless steel, but still widely used in applications where good corrosion resistance and low cost are important.

430 | 440 | 430LI | 434 | 436 | 444

MARTENSITIC

The least common type of stainless steel, known for its high strength and hardness, but also the least corrosion-resistant.

410 | 416 | 420 | 420LC | 440A | CUSTOM 450® | CUSTOM 455®

DUPLEX STAINLESS STEEL

A combination of austenitic and ferritic stainless steel, offering high strength, weldability, and good corrosion resistance.

Duplex Alloy 2205 | Duplex Alloy 2304 | Duplex Alloy 2507

PRECIPITATION HARDENING STAINLESS STEEL

Can be hardened by heat treatment, offering high strength, hardness, and good corrosion resistance.

15-7 MO® | 17-4 PH® | 17-7 PH® | A286 | AM350®

Stainless Steel Characteristics

Packaging

Spools – Reels

<1 lb to 1,000 lbs

Oscillated Coils

from 50 lbs up to 1,000 lbs