Your Vision. Our Wire. Let’s Make It Happen.

Our experienced staff and cutting-edge wire shaping equipment is ready to produce the flat wire you need for your next project. At United Wire, we know every project and application is different. From <1 lb. to 1,000 lb. spools/coils, or cut lengths from 0.250″ inches to 40 feet, we’re proud to offer customized solutions for every requirement.

Many edges available

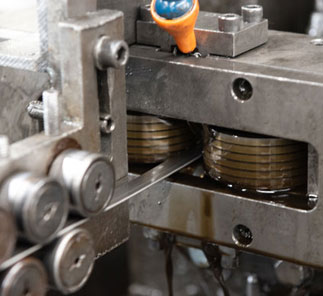

Our Flat Wire Products come in a variety of Edges such as Square, Natural Round, Full Round or square with a Broken/Chamfered Corner. These edges are produced by cold rolling through a mill or a turks head.

Our Flat Wire sizes are available up to .750 inches in width and .002 to .187 inches thick and are available in all Alloys. (Plating options also available).

Did You Know?

You Can Maximize Your Efficiency

Use Flat Wire For Your Stamping Applications!

Our Custom Flat Wire Provides a More Economical Alternative To Strip, Available Up to .750″ Wide:

- Fewer Set Ups and Less Down Time:

- 1000 lb continuous coils/reels with no welds

- Faster Run Speeds with Less Scrap:

- Camber ½” max in 8 ft or less

- Smooth edges, rounded corners

- Precise Quality: Tighter Tolerances:

- +/-.0005” tolerance on gauge/thickness

- +/-.003” tolerance or less on width

We create the highest quality wire for the following industries:

Edges Classifications – Let Us Know Your Preference!

No. 1 Edge

A Smooth, uniform, round or square edge, either slit or filed or slit and edge rolled as specified.

No. 2 Edge

A natural round mill edge carried through from the hot rolled band. Has not been slit, filed, or edge rolled. Tolerances not closer than hot-rolled strip limits.

No. 3 Edge

Square, produced by slitting only. Not Filed. Width tolerances close.

No. 4 Edge

A round edge produced by edge rolling either from a natural mill edge or from slit edge strip. Not as perfect as No. 1 Edge. Width tolerances liberal.

No. 5 Edge

An approximately square edge produced by slitting and filing or slitting and rolling to remove burr.

No. 6 Edge

A square edge produced by square edge rolling, generally from square edge hot-rolled occasionally from slit strip. Width tolerances and finish not as exacting as No. 1 Edge.

Our flat wire is produced by cold rolling either redrawn round wire or rod. Depending on the finish temper or the amount of reduction, an annealing process may be required during the flattening process. Some of the advantages of flat wire are tight tolerances, less camber, and a smoother edge.